|

Address:QingShan Road No.689,Licang area,Qingdao China |

|

Tel:+8617753219835 |

|

Mobile:+8617753219835 |

|

Email:Henry@chinaluckysteel.com |

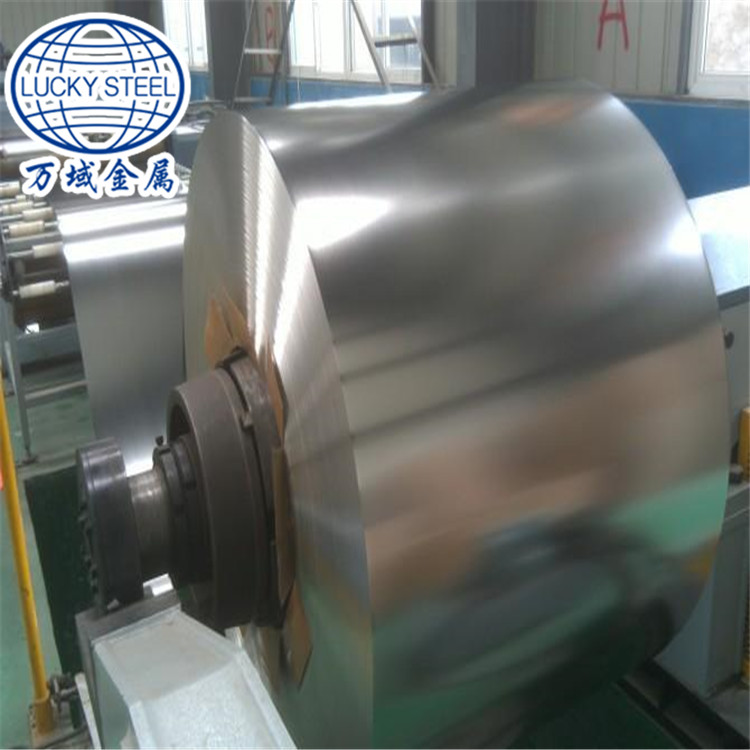

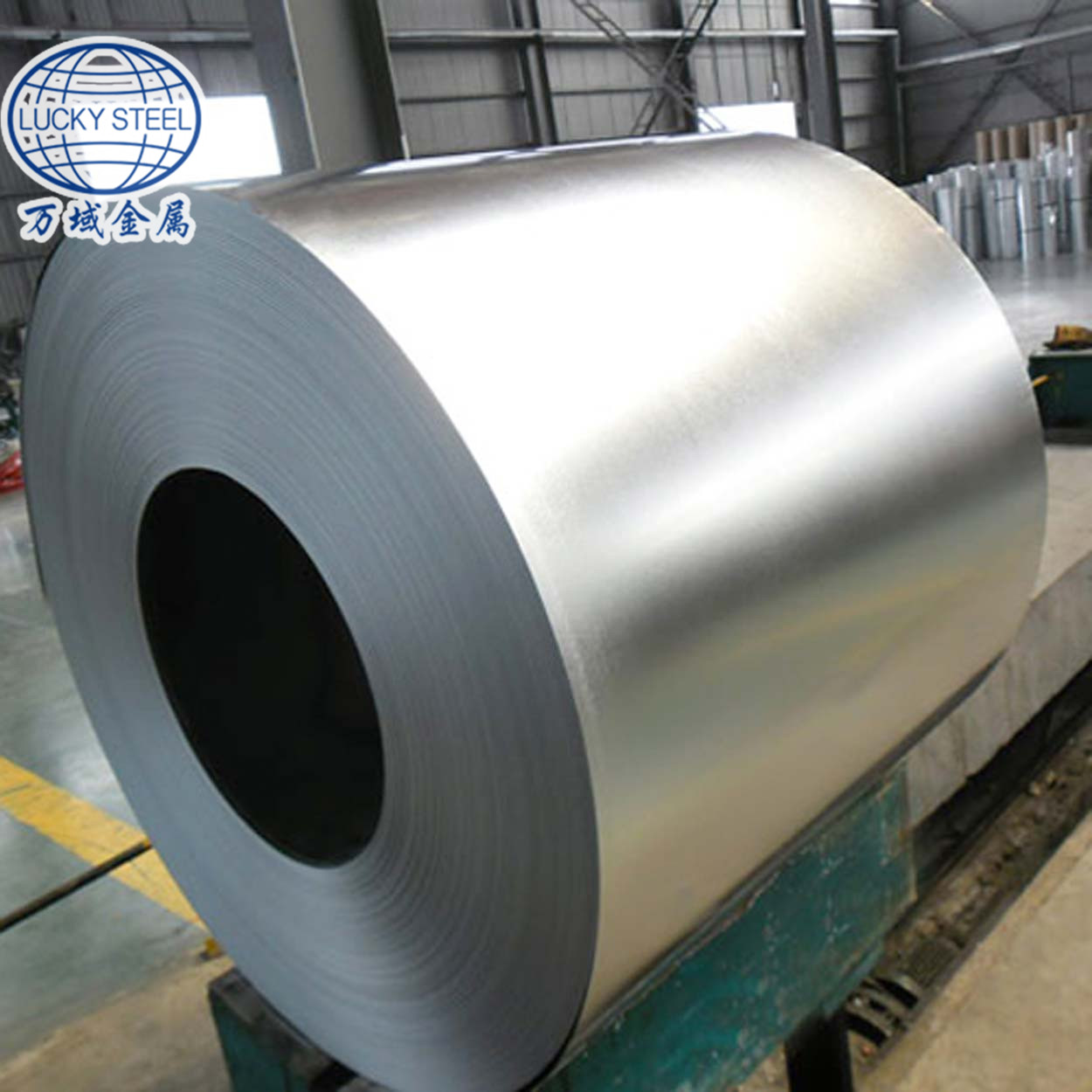

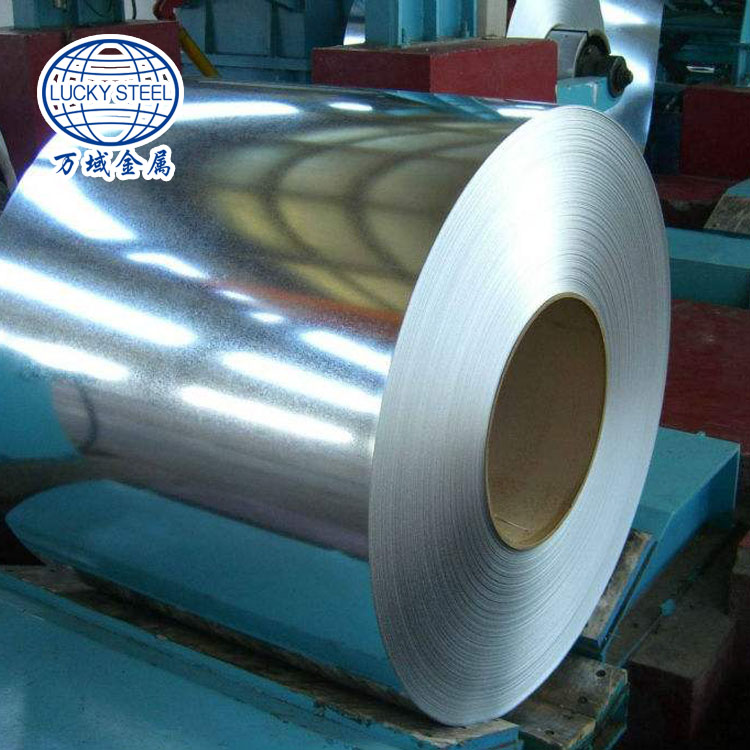

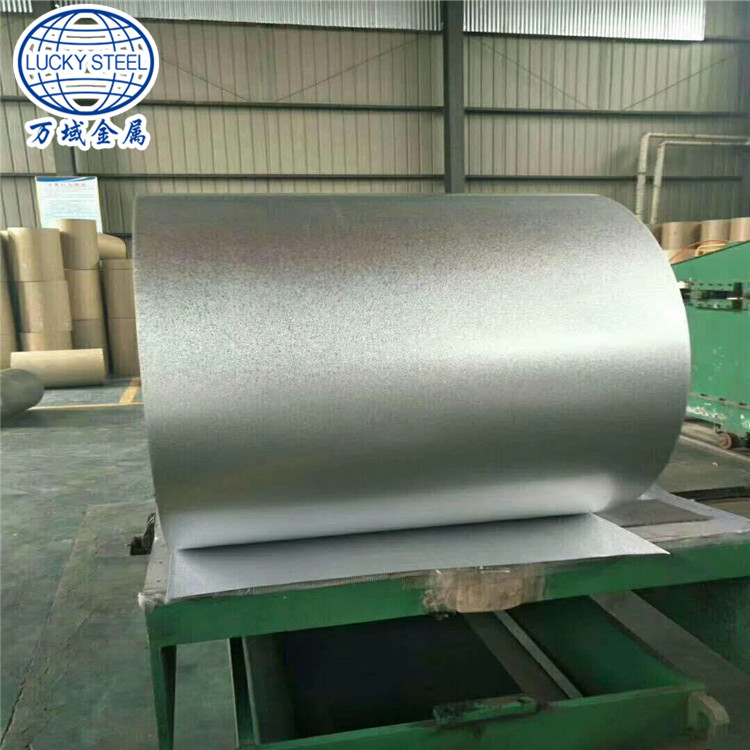

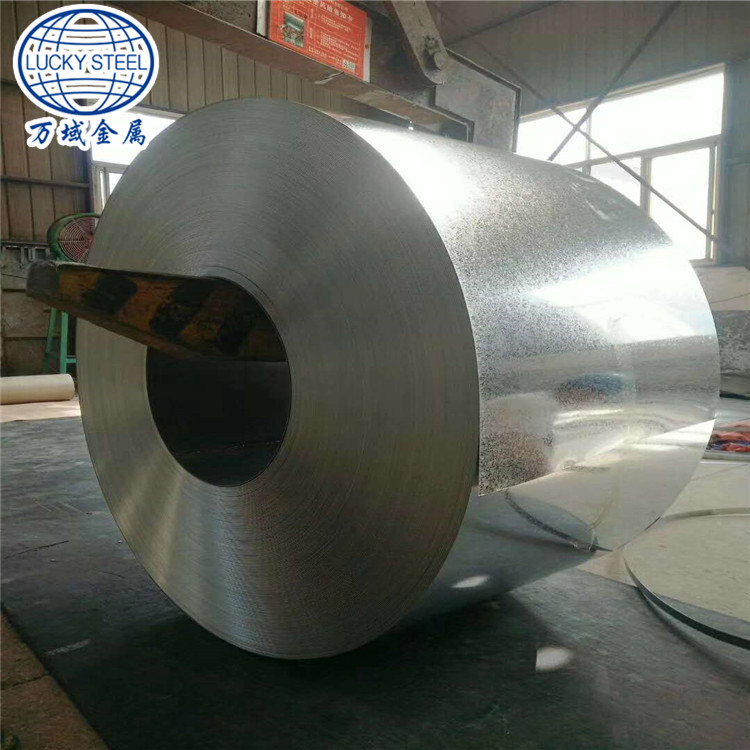

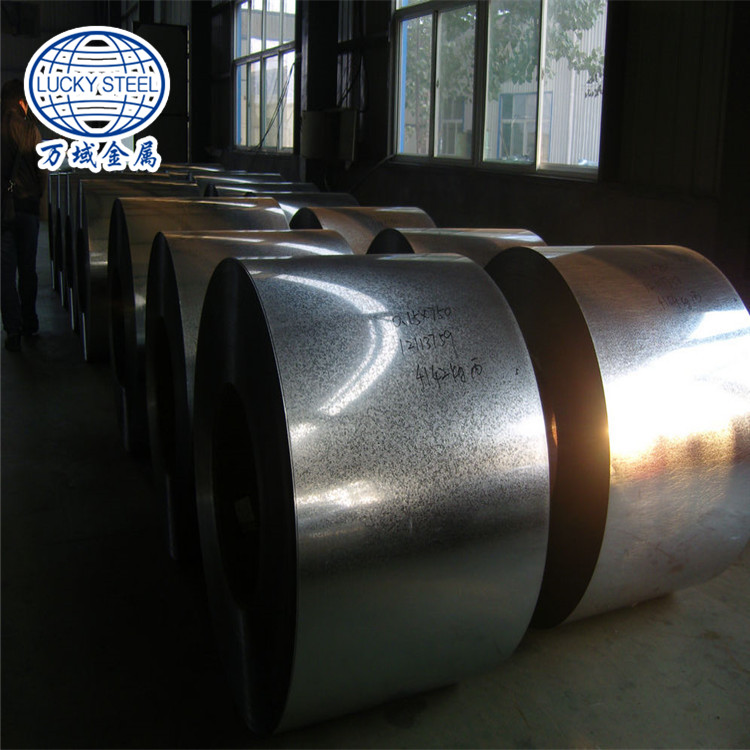

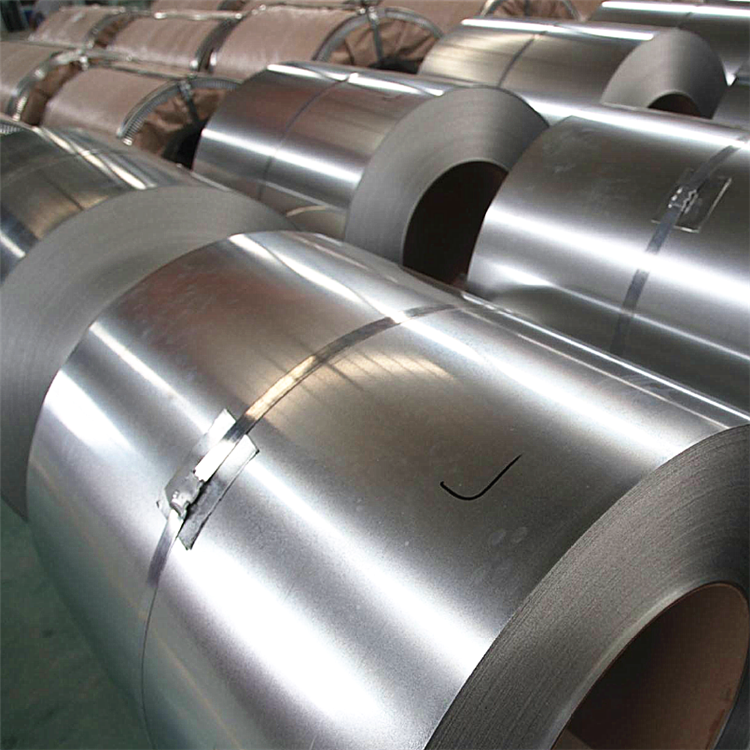

Hot-dip galvanized steel coil with DX52d grade

Small Spangle Galvanized Steel Coil With SGCC Grade high Quality

Galvanized Steel Coils/GI Steel Zero Spangle

Galvanized Steel Coil 30-275g/m2 Hot Dipped Zinc Coating China

Hot Dipped Zinc Coated GI Steel Coil

Hot dipped gi galvanized steel coil z275 with 0.3mm thickness China

China Gi steel coils factory Steel Product

Zinc coating steel coil with Z120g/m2 zinc coating for Uruguay

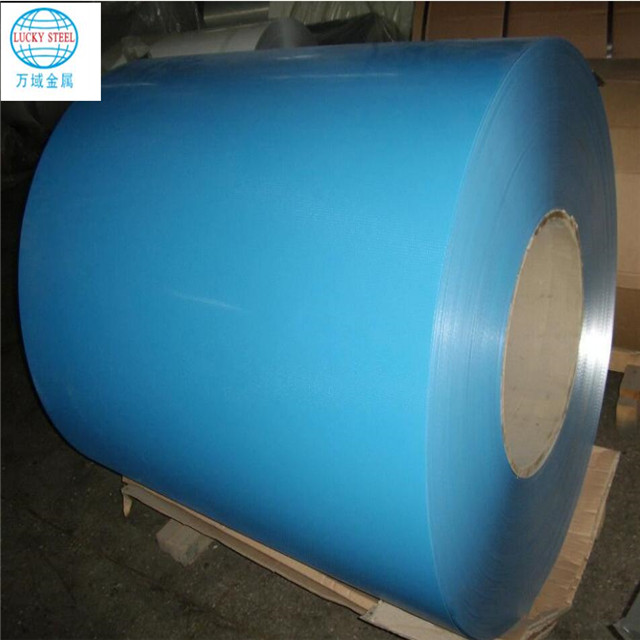

PPGI Prepainted Galvanized steel Coils

Hot dipped galvanized steel coil Z275 G90 2.0mm thickness

hot dipped galvanized steel coil for metal roofingfactory price

SGCC GALVANIZED STEEL COIL WITH Z275G/M2 G90

HDGI HOT DIPPED GALVANIZED STEEL ROOFING COILS AND SHEETS

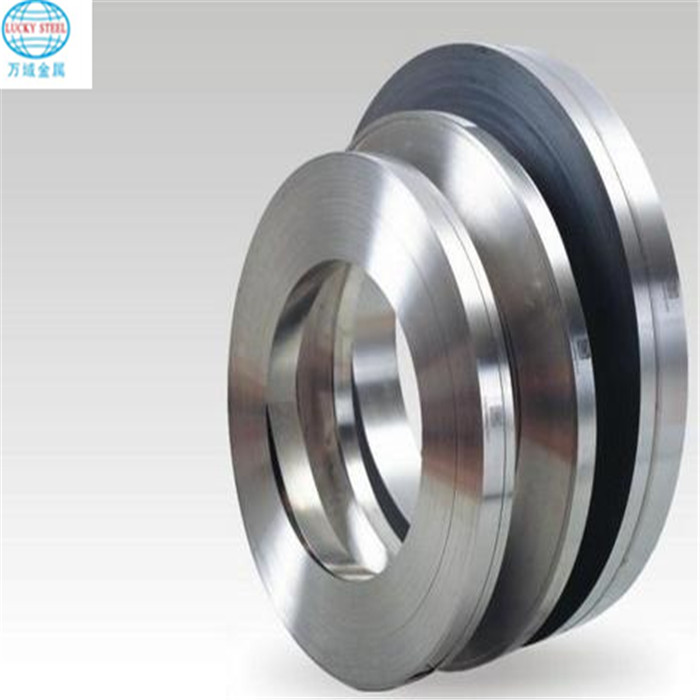

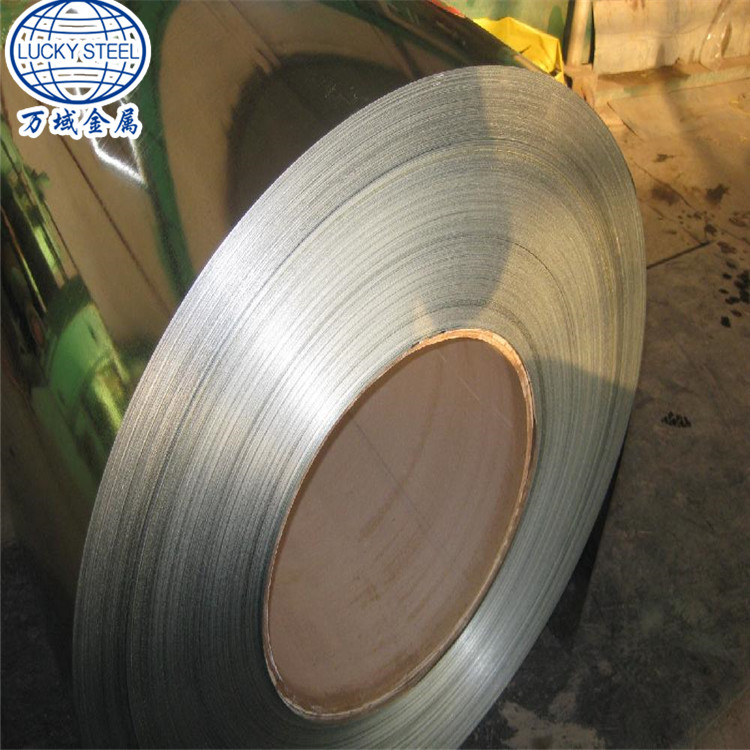

galvanized steel strip/steel edging strip

HDGI Hot Dipped Galvanized Iron Steel Roofing Coils and Sheets

Zero Spangle Galvanized Steel Coils/GI Steel

China Galvanized steel coil 30-275g/m2 hot dipped zinc coating

1050 1060 1100 1200 3003 3105 5005 5052 anodized PE /PVDFColor Coated Aluminum Coil

Hot dipped gi galvanized steel coil z275 with 0.3mm thickness

Gi zinc coated galvanized steel coil with JISG3302 grade

Suppliy zinc coated galvanized steel coil with 70 gauge

BOXING galvanized steel coil manufacturer/Gl coils//zink coated coils

Zinc coating steel coil with zero spangle

Prime hot dipped zinc caoted gi steel coil

Hot dipped gi galvanized steel coil 0.4mm thickness

PPGI/PPGL/ Prepainted Galvalume steel coils/ galvanized steel coils

Zinc coating steel coil for roofing sheet

PPGI for metal roofing

galvalume coil manufacturers in china

high quality galvalume steel coil/sheet

Supply 1000mm Aluminum steel coil

Zinc coating dx51d z100 galvanized steel coil

Zinc coating steel coil for roofing sheet

galvanized steel coil 0.3-0.4mm thickness

Supply dx51d zinc 100 galvanized steel coil

Zinc coating steel coil for roofing sheet

Small spangle galvanized steel coil with SGCC grade

Small spangle galvanized steel coil with SGCC grade

Prime hot dipped galvanized steel coil

china professional galvanized steel coil manufacturer for Uruguay market

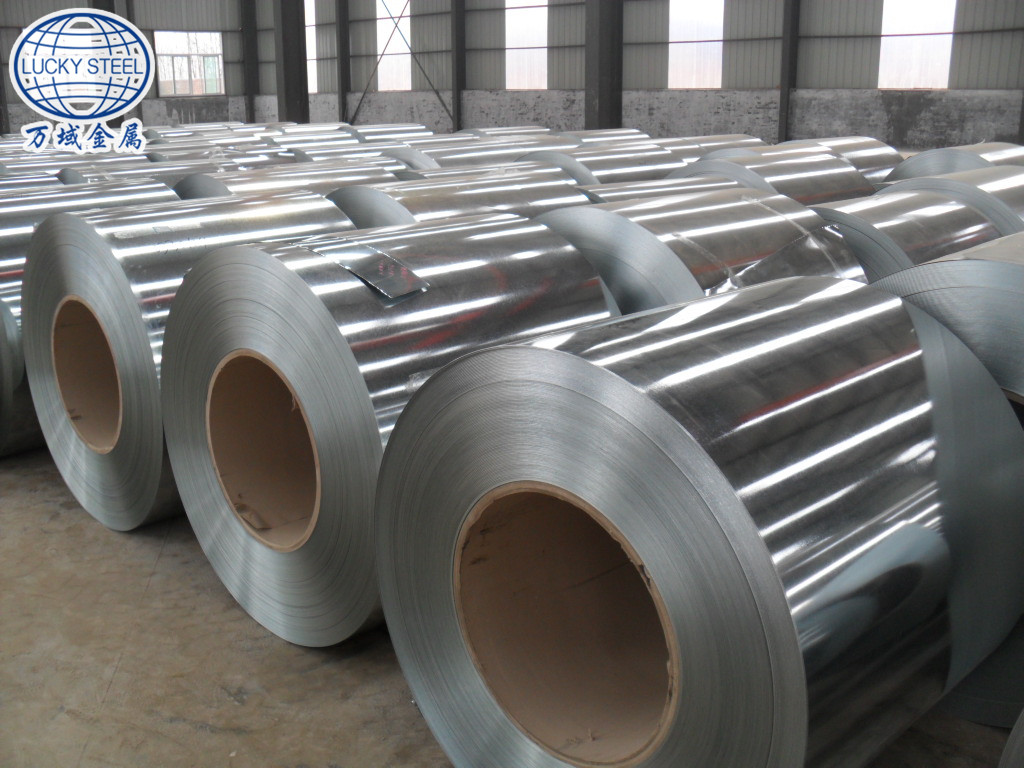

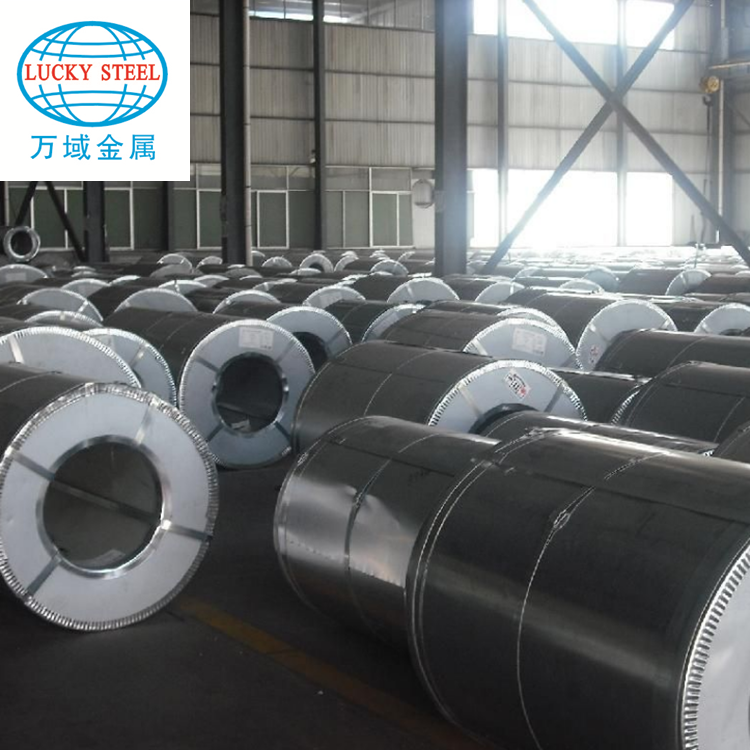

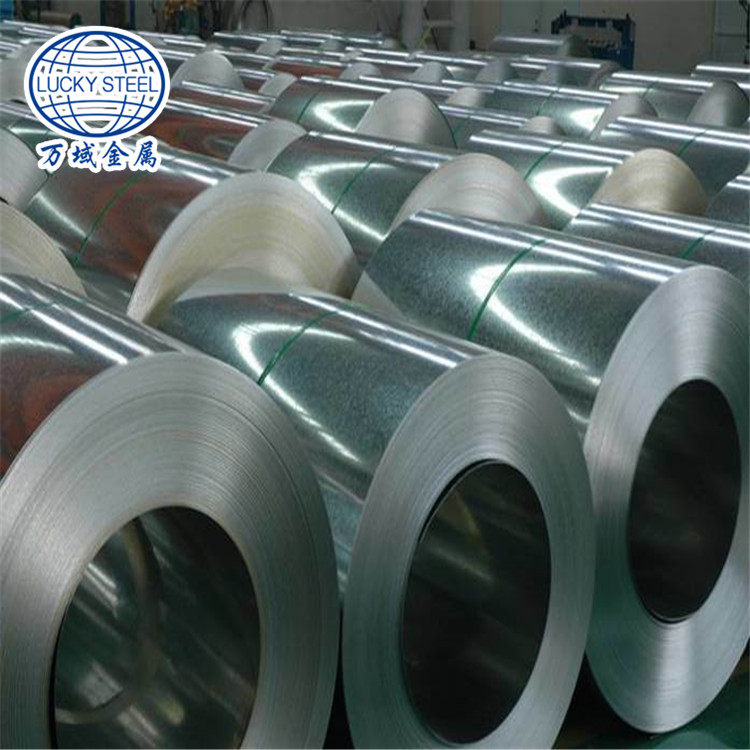

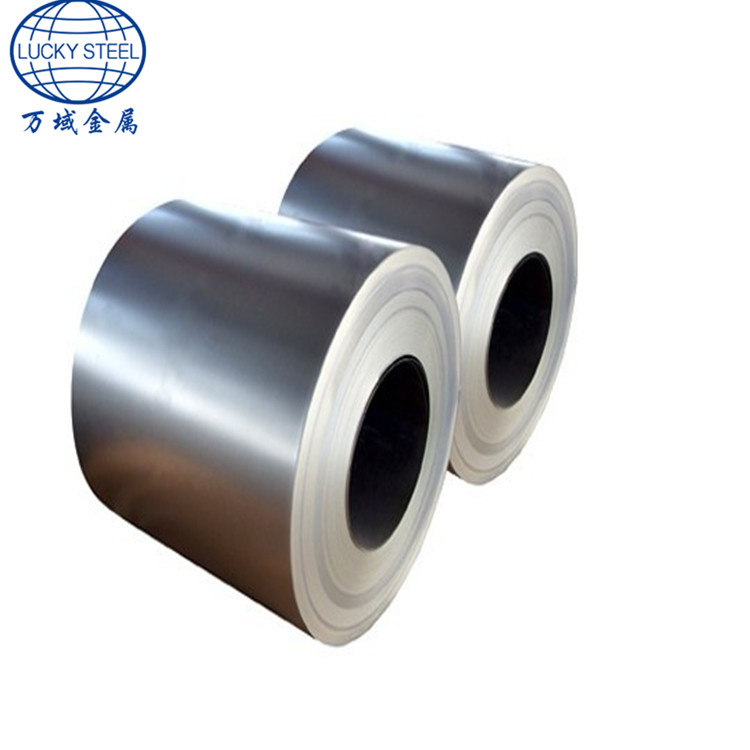

Coil, also known as steel Coil. Hot-rolled steel coil, cold-formed into a roll. For the convenience of storage and transportation, it is convenient to carry out various processing (for example, processing into steel plate, steel strip, etc.).

Molding is mainly hot-rolled coil and cold-rolled coil. Hot rolled coil is processed product before recrystallization of billet. Cold rolled coil is the follow-up of hot rolled coil. Coil general weight is about 15-30T. This year, China's hot-rolled production capacity continues to expand, there have been dozens of hot-rolled production lines, there are some projects to be built or put into operation soon.

Steel coil sales mainly for large customers, the general user does not open the device or a limited amount of use. Therefore, the follow-up processing coil will be a promising industry. Of course, the larger mills now have their own unwinding and leveling project.

It consists of 55% aluminum, 43% zinc and 2% silicon solidified at a high temperature of 600 ° C. The whole structure consists of aluminum-iron-silicon-zinc and forms an alloy of dense quaternary crystals.

The company is located in:

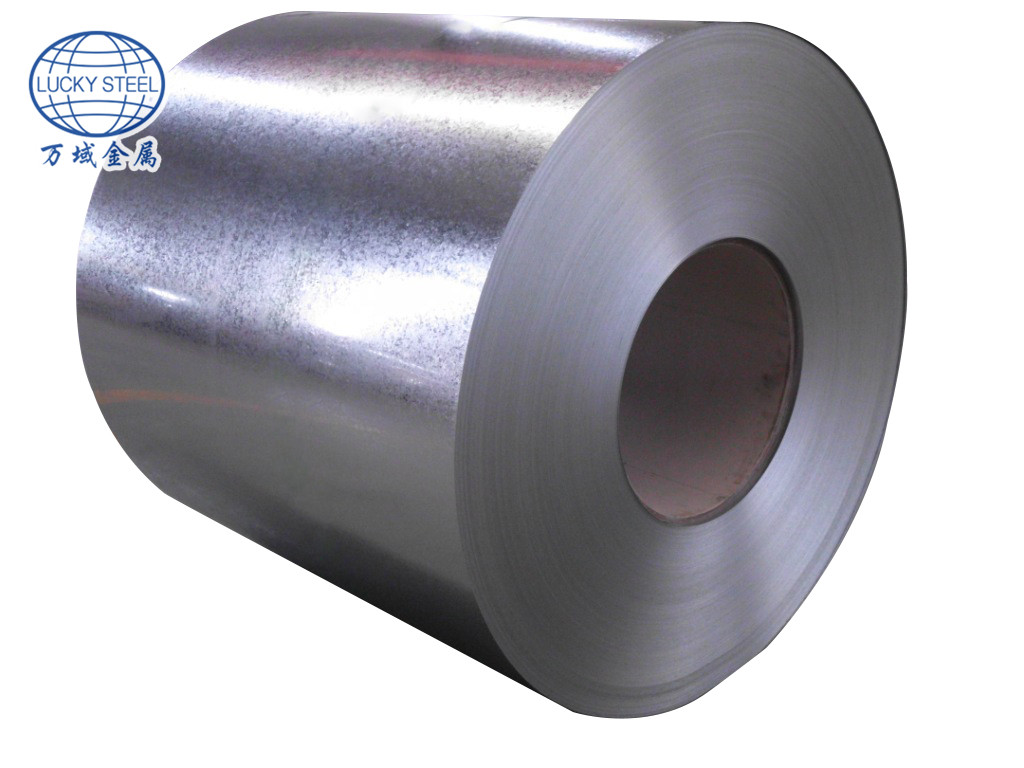

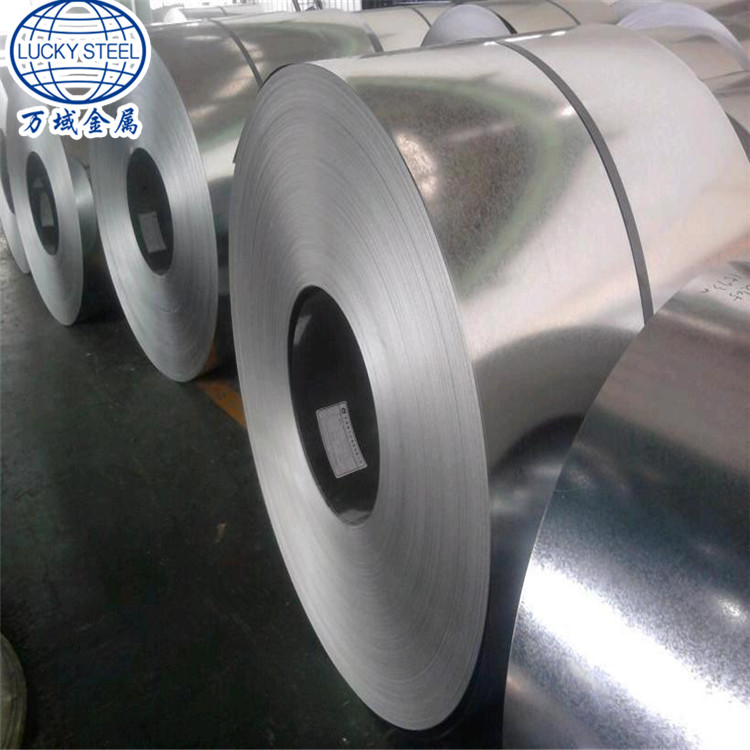

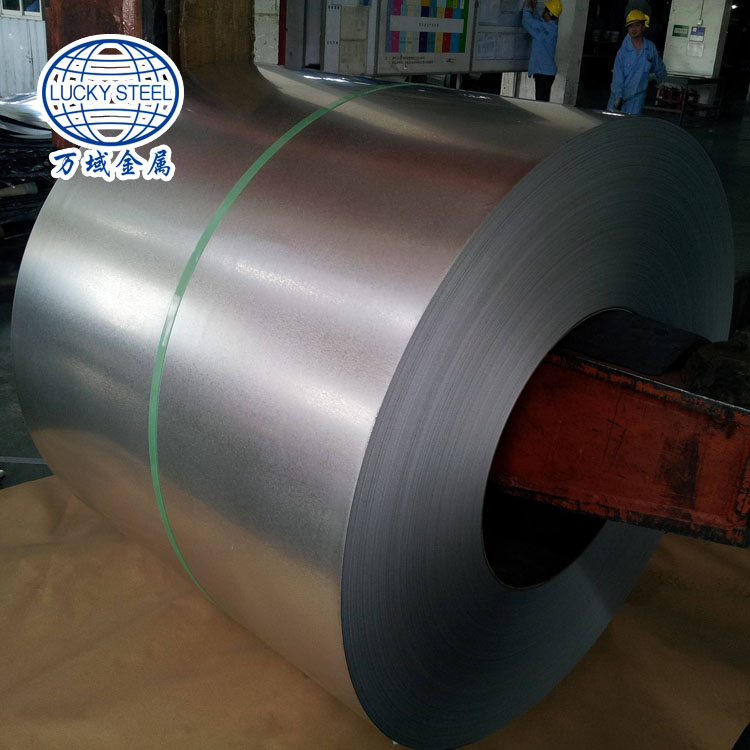

Galvanized steel has many excellent features: strong corrosion resistance, is 3 times the pure galvanized sheet; the surface of a beautiful zinc flower, can be used as building house board. Its characteristics are: corrosion resistance

(The corrosion resistance of "Galvanized Steel Coil" is mainly due to the protective function of aluminum and aluminum.When the zinc is worn, the aluminum forms a dense layer of alumina to prevent further corrosion of the corrosion-resistant material

internal. ), Heat resistance (aluminum-zinc alloy steel plate has good heat resistance, can withstand 300 degrees Celsius temperature, and the high temperature oxidation resistance of aluminum plate is very similar),

Heat Reflectance (Galvanized steel has a high thermal reflectance, twice that of galvanized steel and is often used as a material for insulation.) Economical (because 55% AL-Zn is denser than Zn small

, So in the case of the same weight and the same thickness of the gold plating, galvanized steel than the plated steel plate area of 3% or more). Galvanized sheet post-processing are: DRY dry; OIL oiled;

Chromate chromic acid passivation; AFP / Galva clean fingerprint resistant; Non-Gr, Gr-free cadmium-free fingerprint resistance. The company is located in:

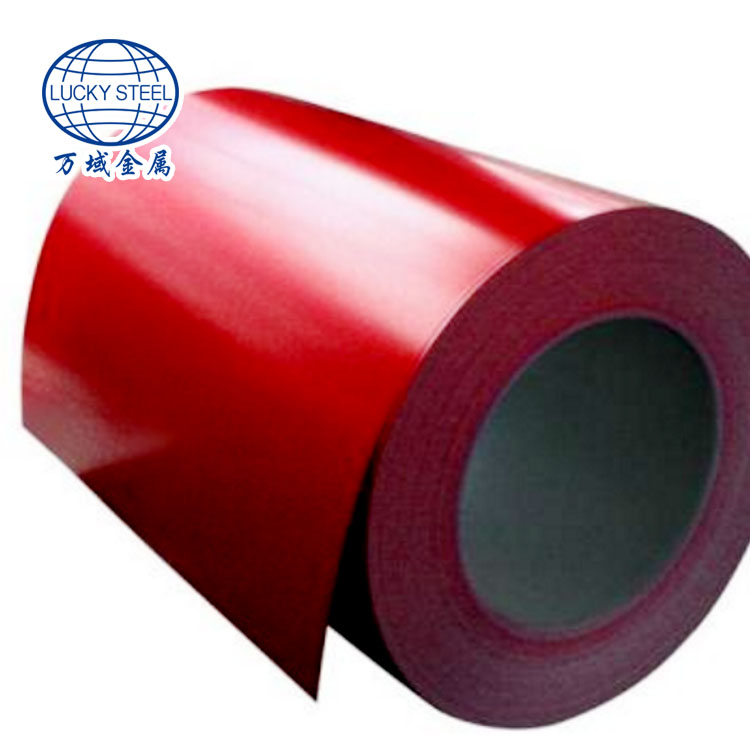

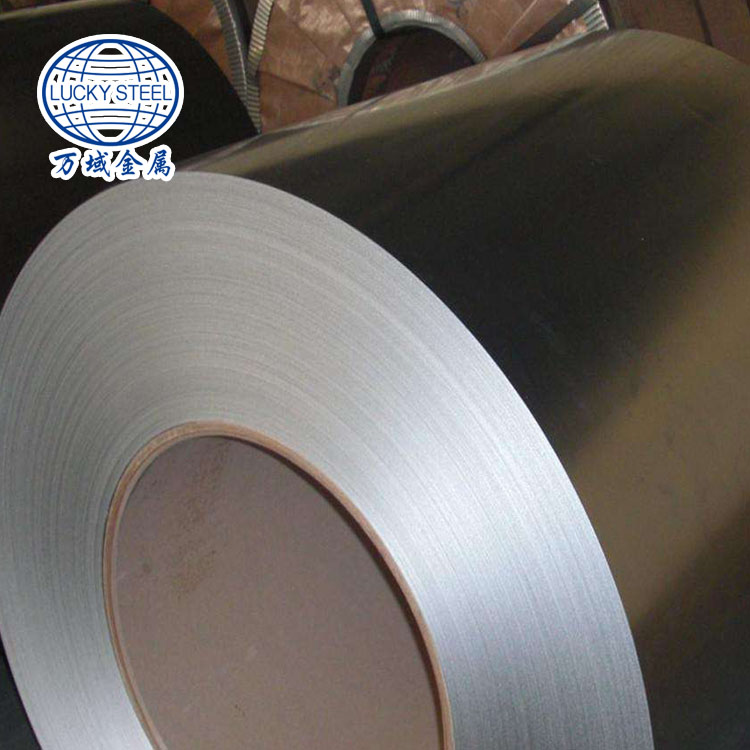

Color coils, organic coated color coils coated in various colors

Board hence the name, referred to as Caitu volumes. The company is located in:

The use of hot-dip galvanized steel strip as a substrate for the color coated steel strip in addition to the protection of zinc, zinc coating on the organic coatings played a protective and covering,

Prevent steel rust, life is longer than galvanized, about 1.5 times. The company is located in:

Caitu volume with light,

Beautiful and good anti-corrosion properties, but also direct processing, mainly used in construction, household appliances, electrical appliances, furniture industry and transport. The company is located in:

Choi Choi coating used according to the use of different environments choose the right resin, such as polyester modified silicone, polyvinyl chloride plastic sol, polyvinylidene chloride. Users can choose according to the purpose.

The company is located in:

Physical properties of steel:

Mechanical properties of steel is to ensure the final performance of steel (mechanical properties) of an important indicator, it depends on the chemical composition of steel and heat treatment system.

In the steel pipe standard, according to different requirements, the tensile properties (tensile strength, yield strength or yield point, elongation) and hardness, toughness,

There are user requirements of high and low temperature performance. The company is located in:

Tensile strength (σb)

The maximum force (Fb) the specimen is subjected to during tensioning,

Out of the original cross-sectional area (So) of the resulting stress (σ), known as the tensile strength (σb), in units of N / mm2 (MPa).

It represents the maximum capacity of a metal material to withstand damage under tension. The formula is:

Where: Fb - when the sample pulled off the maximum force, N (Newton);

So - the original sample cross-sectional area, mm2.

Yield point (σs)

With yielding metal material, the sample does not increase the force during the stretching.