|

Address:QingShan Road No.689,Licang area,Qingdao China |

|

Tel:+8617753219835 |

|

Mobile:+8617753219835 |

|

Email:Henry@chinaluckysteel.com |

China Carbon steel coil manufacturer High Quality

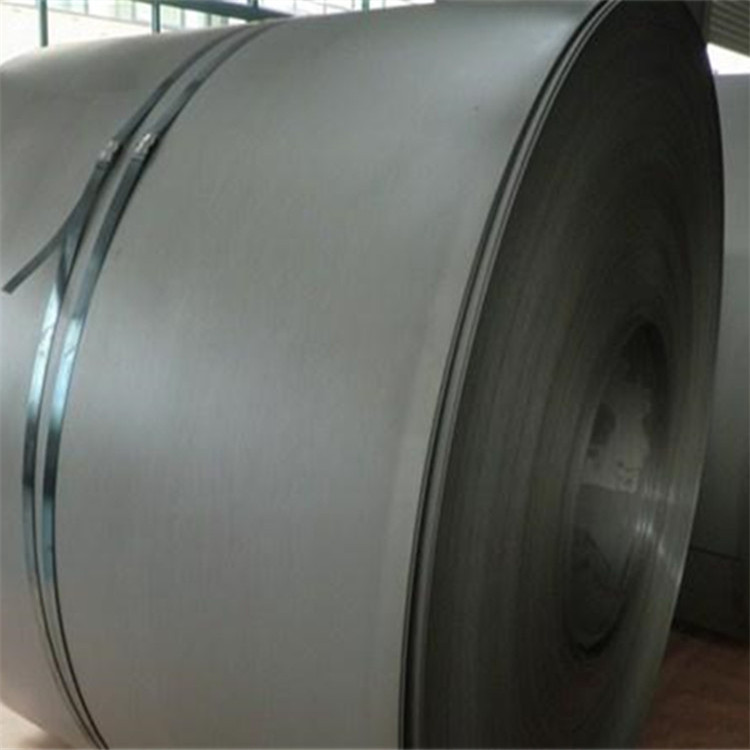

China manufacture Mild steel coil Wildly Used

Hot rolled steel plate price

Factory price hot rolled steel coil

Hot Rolled Steel Coil With Q235B Grade

hot rolled steel plate A36

hot rolled steel checker plate

hot rolled steel plate and sheet

Manufacture Mild steel sheet

Manufacture Mild steel plate

Manufacture Q235 Q345 A36 HR sheet China

China Carbon steel coil manufacturer

hot rolled coil prices

China manufacturer HR coil

China Manufacture Hot rolled Steel Coil Steel Sheet/Plate

China manufacture Mild steel coil

Hot rolled (Hot rolled) is a Hot rolled coil. It is made of slab (mainly cast billet). After heating, it is made into strip steel by roughing mill group and finishing mill group. From finishing the last hot steel strip mill out through laminar flow cooling to the set temperature, which consists of the winder coil, steel coil after cooling, according to the different needs of users, with different finishing line (flat, straightening, transverse or longitudinal cutting, inspection, weighing, packaging and logo, etc.) and become a steel plate, flat roll and longitudinal cutting steel strip products. Material: Q235B, Q345B, SPHC, 510L, Q345A and Q345E Cold rolled coil, often used in steel industry, different from hot rolled coil. It refers to the steel belt which is rolled into a certain thickness at normal temperature and rolled by rolling machine. Compared with hot rolled coil, the surface of cold rolled coil is bright, the finish is high, but it will produce more internal stress, and often annealed after cold rolling. Classification: SPC SPCD SPCE (Galvanized steel coils), galvanizing is the surface treatment technology that is coated with zinc on the surface of metal, alloy or other materials for the appearance of aesthetics and rust prevention. Now the main method is hot galvanizing. The production process of hot plate and zinc plate mainly includes: preparation of raw plate, pre-plating treatment, hot dip plating, post-plating treatment, finished product inspection, etc. According to custom, according to pre-plating treatment method. Aluminum zinc plating (Galvalume steel coils), aluminium zinc steel plate is aluminum zinc alloy composition, aluminum, zinc and 43% 55% from 43% silicon at 600 ℃ high temperature solidification and composition, its whole structure by aluminum - iron - silicon - zinc, forming dense four yuan form an alloy of crystal. Aluminum - plated zinc plate has many excellent properties: strong corrosion resistance, 3 times of pure galvanized sheet; The surface has beautiful zinc flowers, which can be used as a building outside the building. Its special

Sex: corrosion resistance (" aluminum and zinc plated steel roll "corrosion resistance is mainly due to aluminum, aluminum protection function. When there is wear and tear of zinc, aluminum and form a layer of dense alumina, to prevent further corrosion of internal corrosion resistance material.)

Heat resistance (aluminum zinc alloy steel plate has good heat resistance, can withstand the high temperature of more than 300 degrees, and is very similar to the high temperature oxidation of aluminized steel plates)

Heat reflectance (the hot reflectivity of aluminized zinc plates is twice as high as galvanized steel, which is often used as a heat-proof material),

Economy (because 55% of al-zn density is smaller than Zn's density, so it is more than 3% larger than that of plated steel with the same weight and gold-plated layer thickness.) The post-treatment of aluminized zinc plate is DRY and DRY; OIL OIL; Chromate Chromate passivation; AFP/Galva clean fingerprinting; Non-gr, gr-free no cadmium resistant fingerprint. Color coils, the name of colored steel rolls with different colors of organic paint. Use hot dip galvanized steel strip for the base material of color coating steel strip besides have zinc layer protection, organic coatings on the zinc layer covering and protection, prevent rust steel belt, service life is longer than galvanized zone, about 1.5 times. The color coating has light quality, beautiful and good anti-corrosion performance, and can be directly processed, mainly used in construction, home appliance industry, electrical industry, furniture industry and transportation industry. The coatings used in color coating are suitable for different kinds of resins, such as polyester silicon modified polyester, polyvinyl chloride plastic and polyvinylidene chloride. Users can choose according to their usage.