|

Address:QingShan Road No.689,Licang area,Qingdao China |

|

Tel:+8617753219835 |

|

Mobile:+8617753219835 |

|

Email:Henry@chinaluckysteel.com |

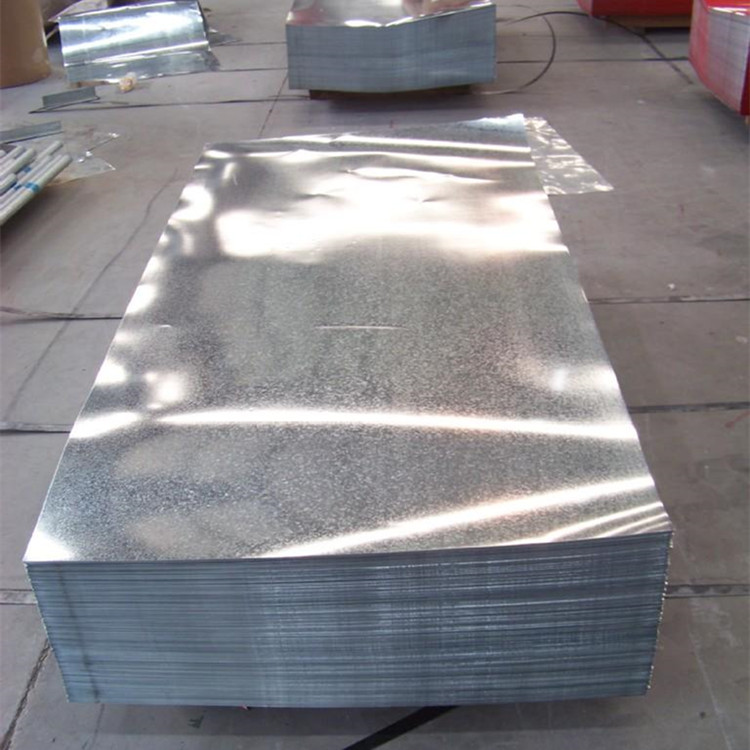

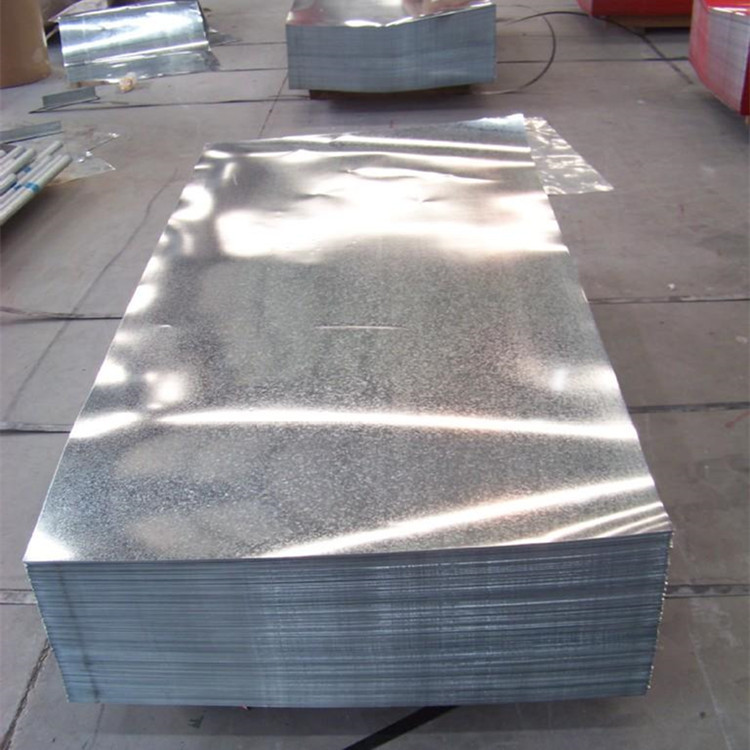

Galvanised steel is mild steel with a coating of zinc The zinc protects the steel by providing cathodic protection to the exposed steel, so should the surface be damaged the zinc will corrode in preference to the steel Galvanised steel is one of the most widely used products, used extensively in the building sector, automotive, agricultural and other areas where the steel needs to be protected from corrosion

Hot-Dip Galvanizing or HDG is a process in which zinc bonds to steel at the molecular level to produce a four-layer corrosion-resistant finish. The first three layers are zinc-iron alloy layers that are actually harder than the base steel. The fourth or top layer is pure zinc.

Thickness: 0.14-2.0mm

Width: 600-1250mm

Popular sizes:

Raw material 762mm to 680,670,660,655,650 mm (after corrugated) and 9 waves

Raw material 914mm to 815,810,790,780mm (after corrugated) and 11 waves

Raw material 1000mm to 930 915,910,905,900,880,875mm (after corrugated) and 12 or 14 waves

Surface treatment: unoil,dry,chromate passivated, non-chromate passivated

Package: seaworthy package

Monthly Output: 30000 tons

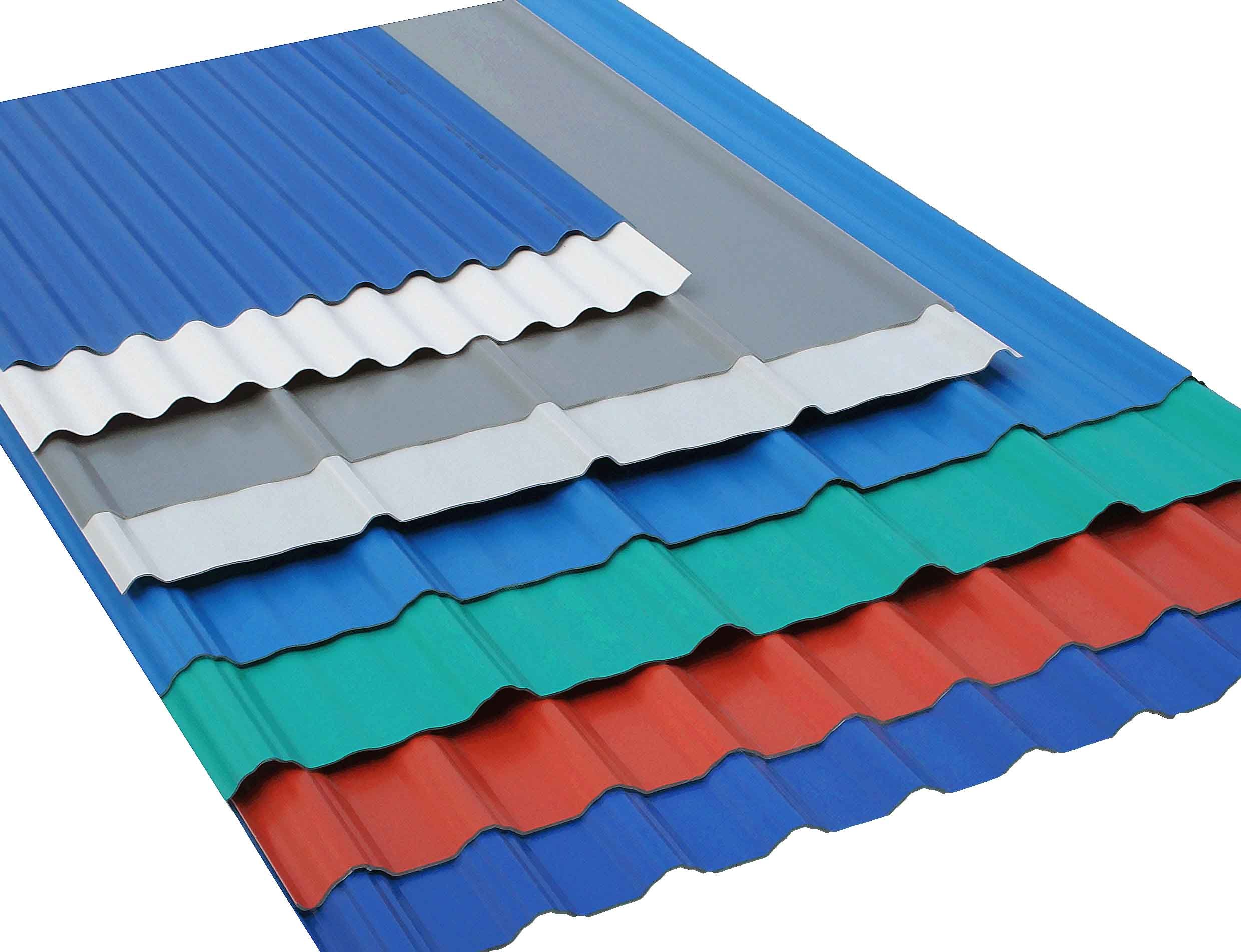

Pre-painted Galvanized steel is a Galvanized steel with a number of paint layers and treatments in a carefully controlled environment in a continuous coil coating line.

Pre-painting can also be done on electrogalvanized coils and cold rolled coils depending on the end-use and application of the steel.

PPGI Steel Coil is better at corrosion resistance. Paint on hot dip galvanized steel make it decaorative and

usually used to indoor and outdoor decoration. Service life of PPGI coils can up to 20 years without fading.(Zn 60g, 25um painted in top and 10um painted in back).Production meets the standard of EN10147 DX51D+Z, JIS G3312 CGCC, ASTM A755M A653M.

Pretreatment Types for Substrate Surface: Normal chemical pretreatment, Chrome free chemical pretreatment. Coating type: Top side two coats, bottom size one coat, Topside two coatings, bottom side two coatings, Topside two coatings, bottom side two coatings(Note: The thickness of bottom side coating is smaller than that of the product type 2/2).

The annual capacity of Color-coated Line is 240,000 tons. We could manufacture top grade steel sheet in building materials plate, automobile plate, electrical appliance plate, solar energy panel, high coating and corrosion resistant plate, MATT plate and plate used for windows and doors.

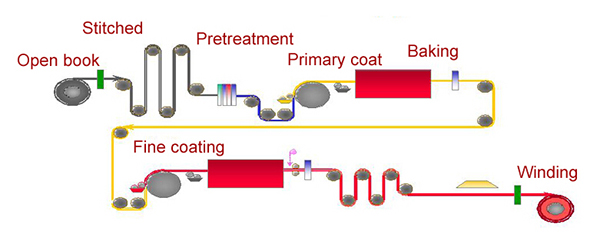

Coating Process

The process of Prepainted Steel Sheets: Uncoiling→Welding→Inlet Looper→Clearning→Chemical Treatment→Primary Coating→Baking of Primary Coating→Baking of Primary Coating → Cooling of Primary Coating → Finish Coating → Baking of Finish Coating → Cooling of Finish Coating → Outlet Looper → Checking → Stamping → Cutting → Coiling.

Packing Details

Standard Export Packing:

4 eye bands and 4 circumferential bands in steel

Galvanized metal fluted rings on inner and outer edges

Galvanized metal and waterproof paper wall protection disk

Galvanized metal and waterproof paper around circumference and bore protection

About the sea worthy packaging: extra reinforcement before shipment to ensure that the goods are safer and less damaged to customers.

Containers for producing petroleum and barrels for containing different kinds of chemical raw materials,

industrial troughs, water tanks, military bullet cases, fermentation vats for beer, barns, distribution cabinets,

containers, fertilizer boxes, etc.

Backboards shells of washing machine, refrigerator, air conditioning and dust collector, wardrobes, tables,

night tables, file cabinets, file boxes, book shelves and other furniture.

Each bare coil to be securely tied with two bands through the eye of coil (or not) and one circumferential, the contact points of these bands on the coil edge to be protect with edge protectors.

Coil then to be properly wrapped with water proof /resistant paper, it then to be properly and completely metal wrapped.

About Our Company

Founded in 2000,China Lucky Steel Co.,LTD has become one of the leading suppliers of steel products in China. We have two factories and four marketing centers with more than 30 production lines and an annual capacity of 900,000 metric tons.

The company mainly specialized in various kinds of steel products, such as hot-dipped galvanized steel pipe, ERW black steel pipe, deformed steel, round bar steel, seamless steel pipe, spiral pipe, angle steel, I-beam, steel channel... We can also customize products according to orders, fulfilling all customers’ requests by providing convenient one-stop service. The company has been certified by BV, and all production process is strictly conforms to the international standard of ASTM A53, BS 1387, JIS G3444, DIN 2440, APL 5L and GB/T 628 to ensure the quality.

Thickness: 0.14-2.0mm

Width: 600-1250mm

Popular sizes:

Raw material 762mm to 680,670,660,655,650 mm (after corrugated) and 9 waves

Raw material 914mm to 815,810,790,780mm (after corrugated) and 11 waves

Raw material 1000mm to 930 915,910,905,900,880,875mm (after corrugated) and 12 or 14 waves

Surface treatment: unoil,dry,chromate passivated, non-chromate passivated

Package: seaworthy package

Monthly Output: 30000 tons

China Lucky Steel Co.,LTD always adhere to the tenet of "loyalty and service first", taking sincerity as our life. "To satisfy customers" is our constant business principle. Since the establishment, we have been playing an active role in city construction, especially in 2008 Qingdao Olympics, Undersea tunnel, sea-crossing bridge. We have accumulated much experience in this line, and our products have been well sold worldwide. Through years' development, we have built up great reputation in quality and services among customers all over the world.

Contact us

Have a question

Serve with heart to achieve mutual benefits.To be the best steel suppler in china. Inquiry(Enquiry) for our latest export price, FOB CIF CFR.

173.jpg)