|

Address:QingShan Road No.689,Licang area,Qingdao China |

|

Tel:+8617753219835 |

|

Mobile:+8617753219835 |

|

Email:Henry@chinaluckysteel.com |

Specification parameter

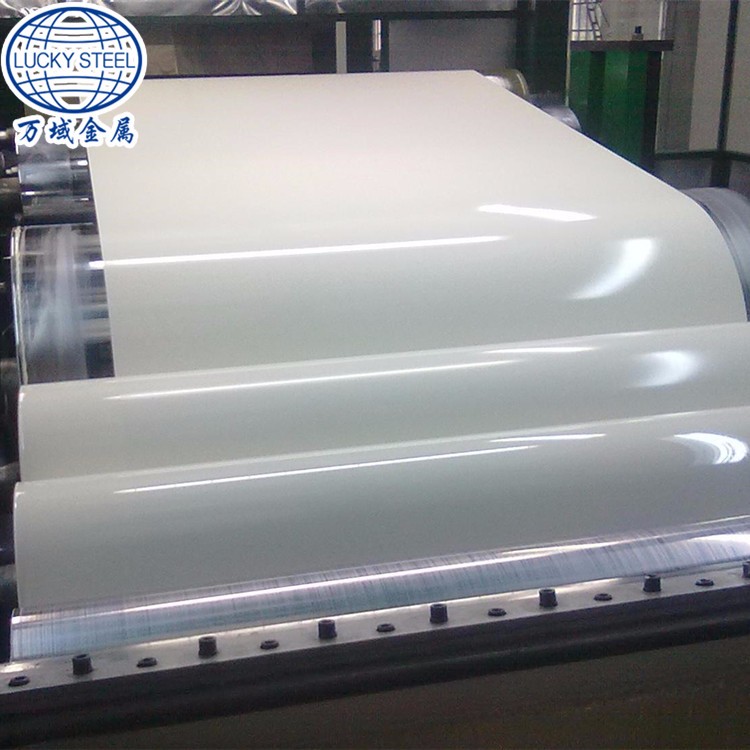

PE(polyester) Coating

PE(polyester) coating:high molecular polymer as monomer and addition of alkyd, is an UV-resistant coating. It can be classified matt and glossy according to coating gloss. The compact molecule structure, makes paint surface luster and smooth,which assure good printing on the panel surface. With an warranty of 8-10 years for weather resistance, it is specially applied for internal decoration and sign board.

PE Color Coated Aluminum Coil:

HAOMEI PE color coated aluminum coil with good PE Paints and high performance of aluminum coil is produced by advanced roller coating. All performance parameters are up to or much higher than related national standards.

The performance of PE color coated coil

| Item | Test Item | >Standard | National standard | Test Result |

| 1 | Color Difference | >ECCA T3 | ΔE≤2.0 | ΔE≤1.5 |

| 2 | Gloss Difference | >ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | >ECCA T1 | Min 14µm | ≥16µm |

| 4 | Pencil Hardness | >ASTM D3363 | ≥HB | HB |

| 5 | T-bend | >ASTM D4145 | ≤3T | ≤2T |

| 6 | Adhesion | >ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | >ASTM D2794 | ≥20kg.cm | ≥20kg.cm |

| 8 | Boiling water Resistance | >GB/T17748 | 2h no change | 2h no change |

| 9 | Solvent Resistance | >ASTM D2248 | 200 times paint remaining | 200 times paint remaining |

| 10 | Salt Resistance | >ASTM B117 | 720 hrs≤grade 1 | 720hrs≤grade 1 |

| 11 | Dirt Resistance | >GB/T9780 | ≤5% | <5% |

| 12 | Color retaining | GB/T16259 | 600hrs △E≤2.0 | △E≤2.0 |

| 13 | Gloss weaken Level | 600hrs ≤ grade 2 | 600hrs ≤ grade 2 | |

| 14 | Chalking | 600hrs No Change | No Change |

PVDF(fluorine-carbon) Coating

PVDF(fluorine-carbon) coating :made of fluorine carbon resin, pigment, ester solvent, after high temperature roasting and baking, the paint is solidified to dry film with super weather resistance. PVDF coating also can be classified as traditional PVDF and nanometer PVDF coating.

A.Traditional PVDF Coating, with KYNAR500 PVDF, two or three times for coating and baking, has good properties of anti-acid, anti-alkali and is durable in atrocious weather and environment, keeping 15 years no unwonted fading. In view of these facts, we recommend this panel applied for external wall cladding.

B.Nanometer PVDF Coating, which different with traditional PVDF is the clear coating. It contains nanometer element, which can protect panel from pollution, Because nanometer has self-cleaning effect, It easy to get rid of dust and pollution by raining or water.

Parameters of PVDF Coating PVDF (KYNAR500 PVDF>70%)

Product Description

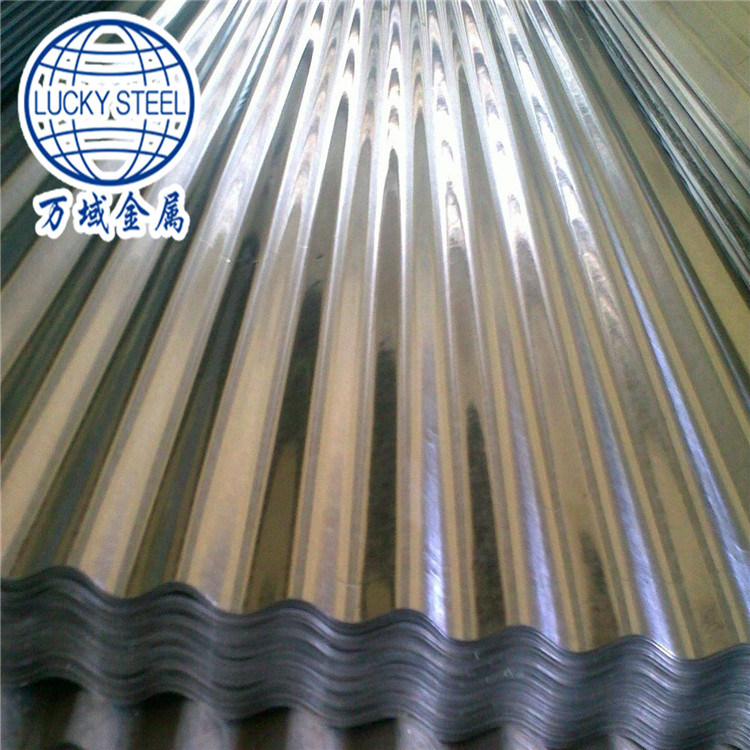

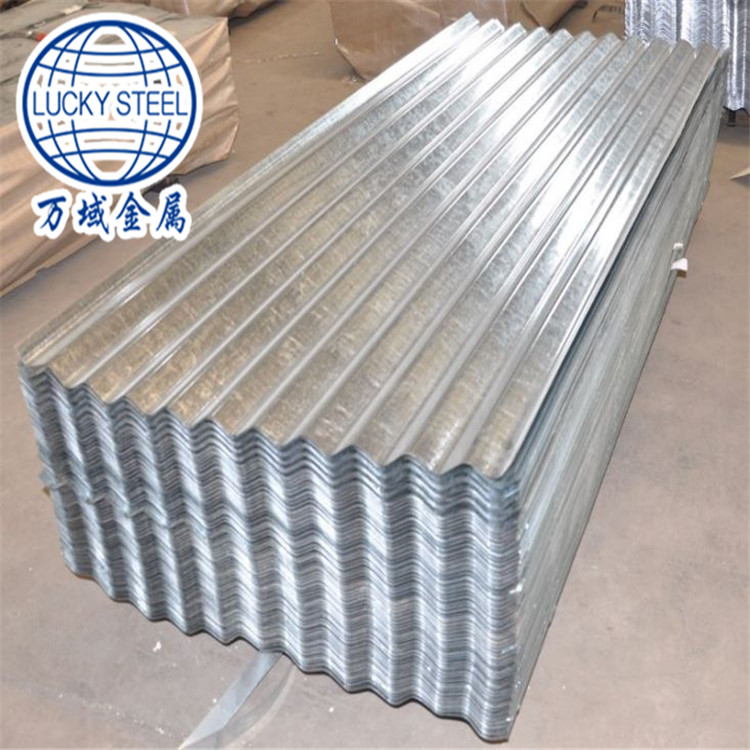

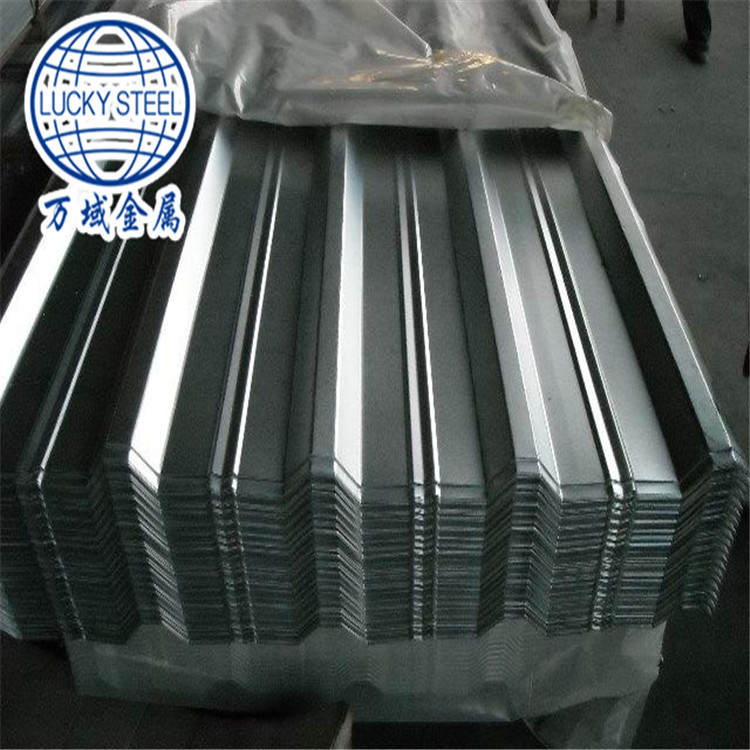

Galvalume finish corrugated metal is one of the most corrosion resistant corrugated materials offered in the architectural roofing and siding panel market. Unlike normal galvanizing, this metal material is an actual combination of aluminum and zinc to provide excellent protection. Galvalume-finished corrugated metal will give you a great product that lasts longer than the traditional galvanized finish.

Galvanized Corrugated Metal is a plain carbon steel sheet coated in a galvanizing process that applies a barrier of zinc to insulate it from the elements. Most of the corrugated roofing and siding products seen today and for many years past are made with a galvanized finish. Galvanized corrugated steel has been the choice for years and has a reputation as a rugged product that can and will last for unlimited time on a structure.

Our Company

Who we are

Founded in 2000, China Lucky Steel Co., Ltd. has become one of the leading suppliers of aluminium products in China. We have two factories and four marketing centers with more than 30 production lines and an annual capacity of 9,000 metric tons.

The company mainly specialized in various kinds of aluminium products, such as aluminium coil, aluminium sheet, aluminium strip, aluminium extrusion... We can also customize products according to orders, fulfilling all customers’ requests by providing convenient one-stop service.

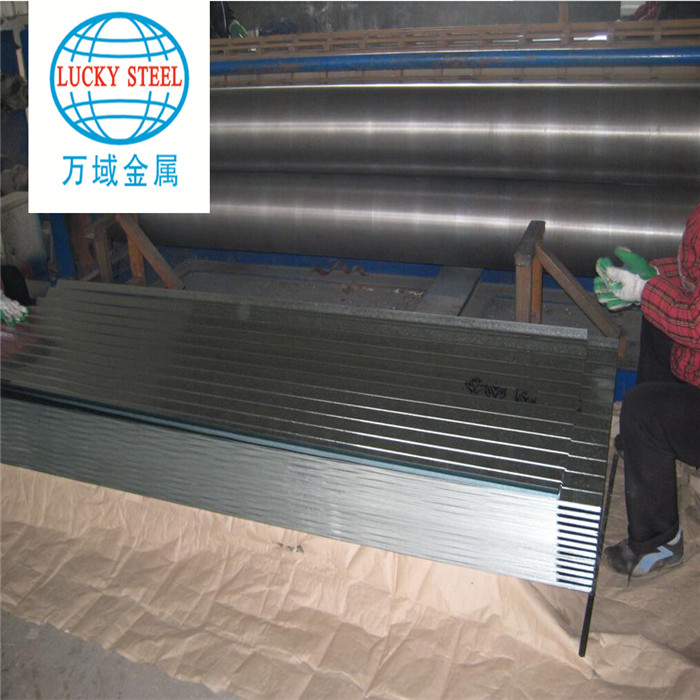

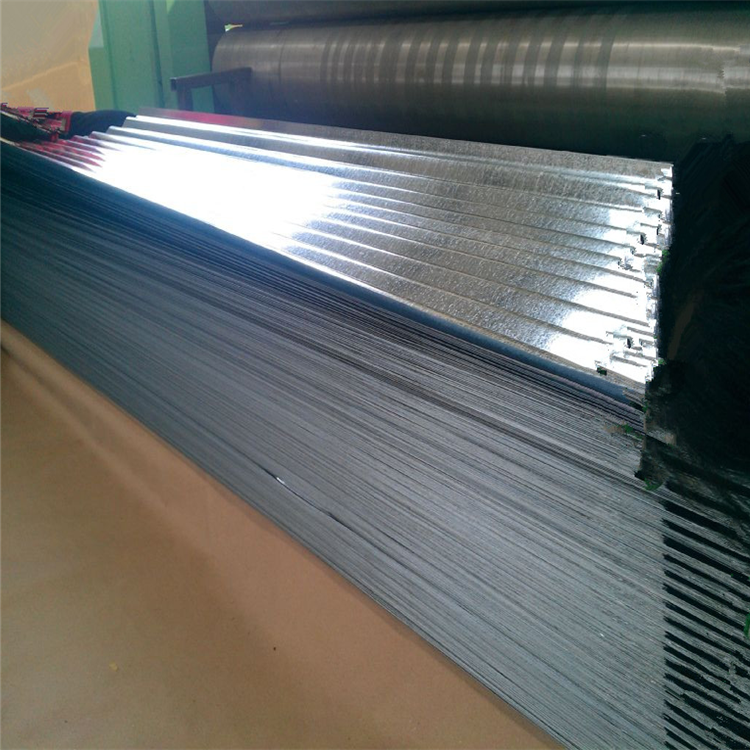

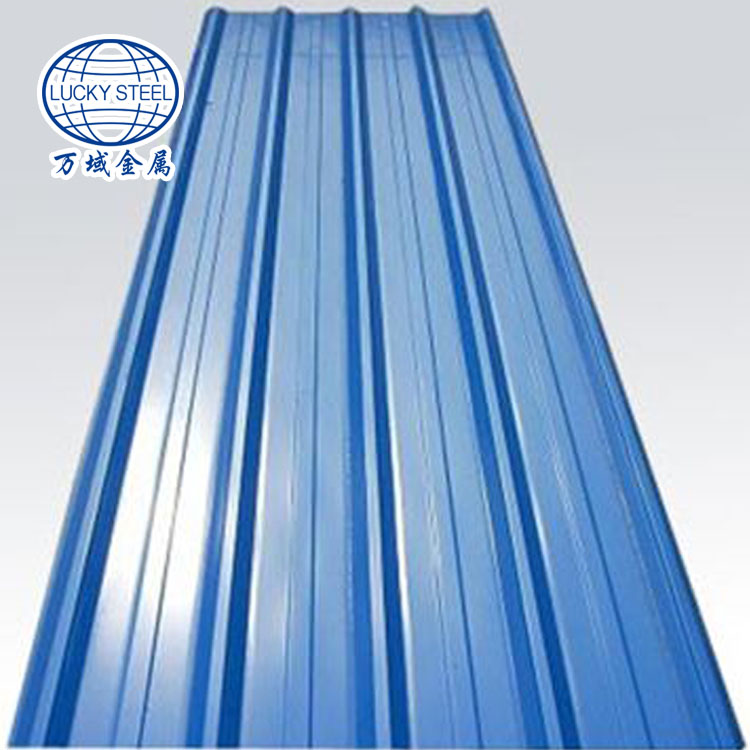

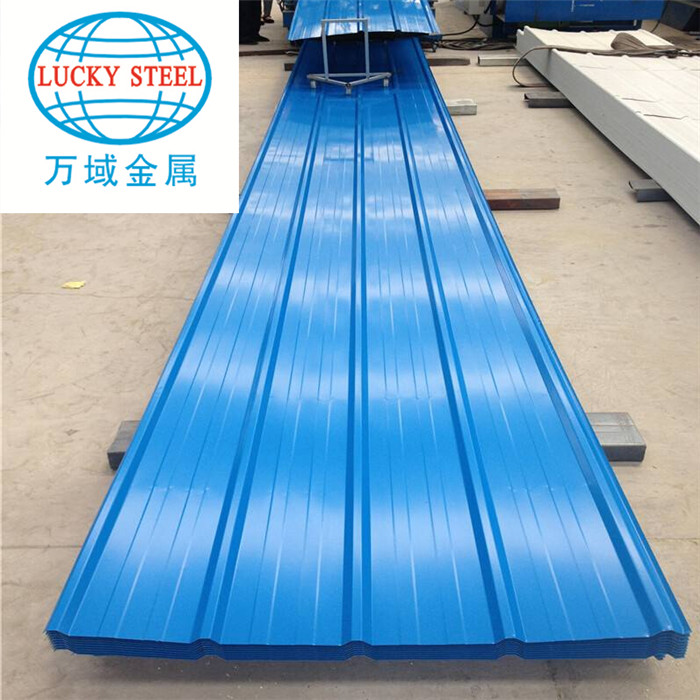

Manufacturing heavy gauge, extra-wide, corrugated roofing and siding materials for use in industrial and commercial buildings, and architectural applications. Corrugated Metals provides custom roll forming and corrugating for a variety of materials including steel, weathering steel, aluminum, and pre-painted finishes.

A wide variety of metal choices include Aluminum, Aluminized I & II, Galvannealed, Stainless Steel, Hot-Dipped Galvanized G-90 through G-285, Cold Rolled CQ (Commercial Quality), ASTM A606 Weathering Steel, and Pre-painted Galvanized & Aluminum.

Experienced corrugated metal design consultation and fabrication featuring “in house” CAD system.

Panels consistently cut to your exact length specifications. Secondary services including stucco embossing, perforating, laminating and precision curving are available.

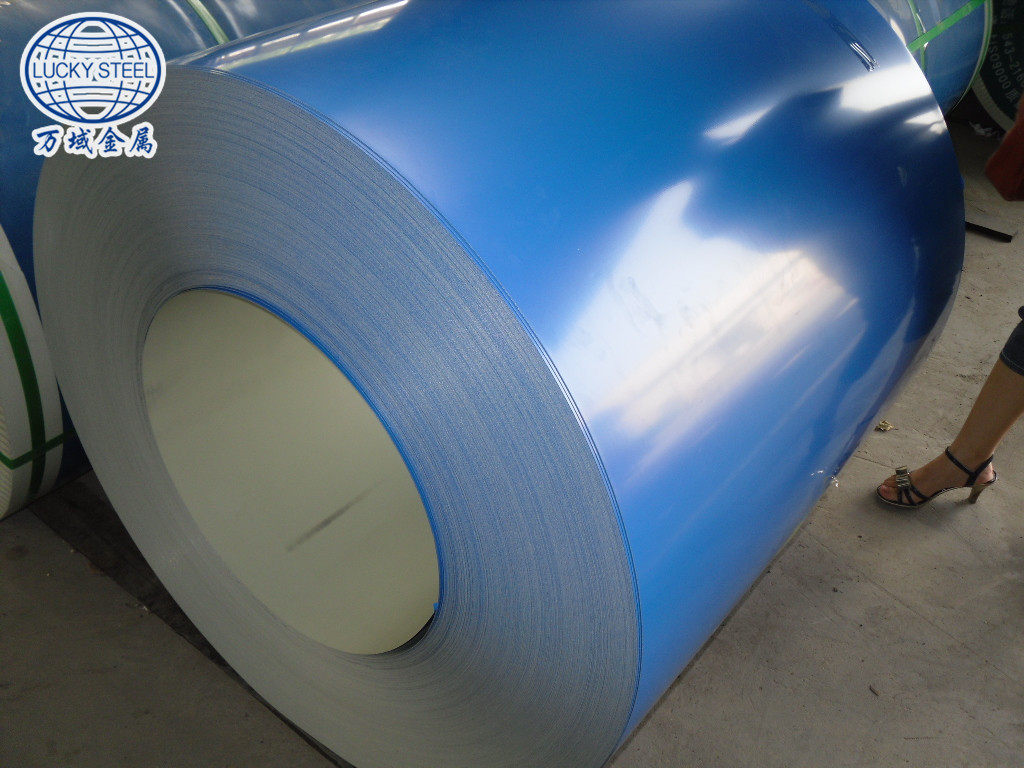

The process of Prepainted Steel Sheets: Uncoiling→Welding→Inlet Looper→Clearning→Chemical Treatment→Primary Coating→Baking of Primary Coating→Baking of Primary Coating → Cooling of Primary Coating → Finish Coating → Baking of Finish Coating → Cooling of Finish Coating → Outlet Looper → Checking → Stamping → Cutting → Coiling.

Roof loads are for positive loads only and are in addition to weight

of panel.Other gauges of steel and aluminum are available upon inquiry.

Maximum allowable stress for Grade A (F) = 20,000 PSI for roofs

and 26,667 PSI for walls where wind is the only load.Loads and spans for carbon steel are based on the AISI Cold Formed

Steel Design Manual.Other gauges of steel may be available upon inquiry.

Our Factory

Roof loads are for positive loads only and are in addition to weight

of panel.Other gauges of steel and aluminum are available upon inquiry.

Maximum allowable stress (FC) = 15,000 PSI, (FT) = 17,000 PSI for

roof and side wall. Stresses have been increased 1/3 for wind loading.Loads and spans for aluminum are based on Aluminum Formed Sheet

Building Sheathing Design Guide.

FAQ

Q1: Are you factory or trading company?

A1: We are factory or manufacturer.

Q2: Can you guarantee your quality?

A2: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

Q3:What is your quality guarantee period?

A3:Quality guarantee term is for one year. Special circumstances can extend the shelf life of two years or three years.You are welcome to contact us at any time.

Q4: How to get your company information?

A4: Find our company China Lucky Steel Co.,Ltd by google Google, Bing, Yahoo, Alibaba.com etc

Q5: What is your MOQ? Can we make a trial order ?

A5: We welcome your trial order 25 T ( one 20 feet container ) . If you want 10 ton , then we can negotiate the price .But we hope large quantity can reduce your cost .

Q6: .What is your main market ?

A6; Products are mainly exported to Europe, America, Southeast Asia, the Middle East and other countries and regions.

Have a question

Serve with heart to achieve mutual benefits.To be the best steel suppler in china. Inquiry(Enquiry) for our latest export price, FOB CIF CFR.